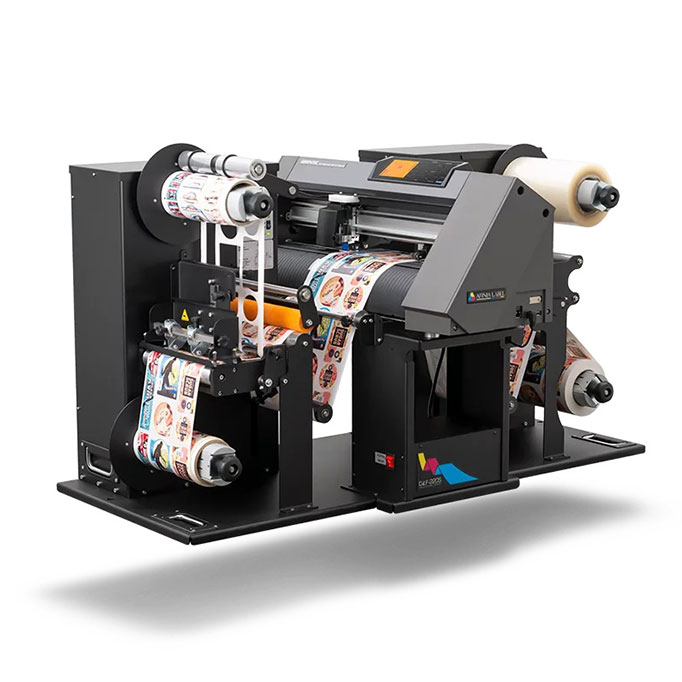

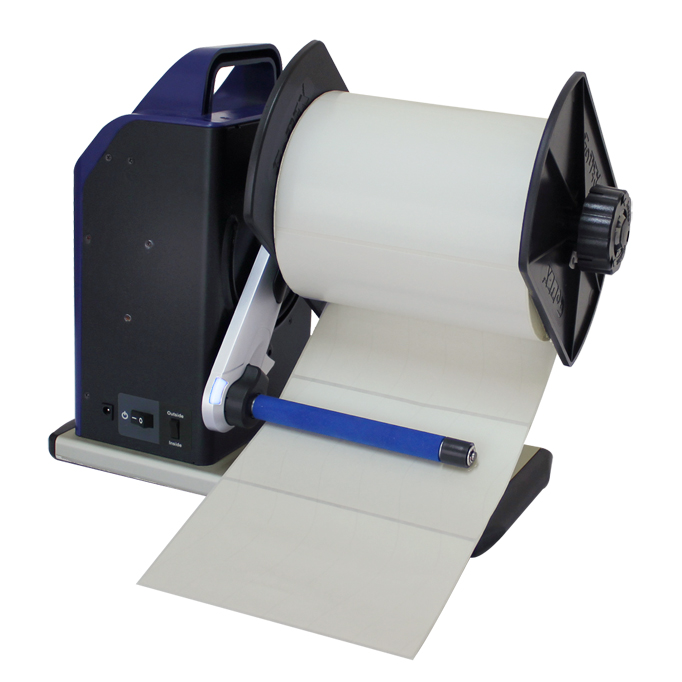

With nearly all large label printers we sell the most common accessory to run along side the printer is a label rewinder. If you’re printing at high speed or there is just a sheer volume of labels then having an automatic rewinder ensures you end up with nice clean label rolls. With a printer like the L801 or L901, they print so quickly that you won’t be able to wind your labels by hand without damaging them or getting in a mess. The label rewinder fixes that.

Reasons to use a label rewinder:

- Wind your labels onto a nice clean roll.

- If you plan to apply your labels using automation you will need tidy rolls on the correct size core for the applicator. Always check what your applicator needs before you purchase a rewinder

- Walk away from your printer while it’s producing a long run with peace of mind that it will be finished when you come back.

- Print at high speed. Some of our winders can cope with speeds of up to 12ips (inches per second). You can’t manually wind labels up at that speed.

For more information on label rewinders including specs & pricing please click on the link below.

In the meantime, here is a video on how to use a label rewinder. You will be surprised at how many times we go to customers and they are using rewinders incorrectly. If you follow the video below you should have no issues attaching your material. If you need any further help please contact our support team on 01264 335118 or support@hdlabels.co.uk