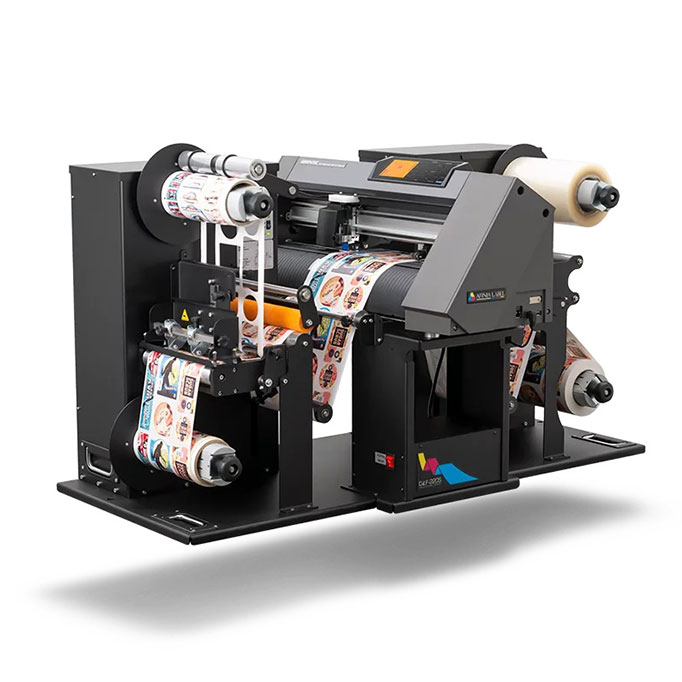

The short answer to this is that it was easier than you think. We installed the Afinia DLP2100 into a large hand sanitiser producer to help them keep up with demand from key services. With the COVID-19 pandemic that we’re all going through. Ensuring a production of hand sanitiser is as important as ever. At HD Labels we were able to supply and install the Afinia DLP2100 allowing fast printing, laminating & cutting of labels on demand. The customer produces many sizes of labels at short notice so they need to print and cut thousands of labels at very short notice. The Afinia DLP2100 allows them to meet these demands.

So how were we able to complete the installation safely?

Luckily the area we were installing the DLP2100 was able to be cleared for the day we would be installing. At HD

What is the process of installing the Afinia DLP2100?

You start with a very big box!

The Afinia DLP2100 is a complete unit and other than the L901 printer being sat on top it comes out of it’s big box in one piece. We remove the panels and break the box down so the machine can be lifted from the box with a fork truck. It’s physically bolted and held in place by the base so this is why it needs lifting out.

Thankfully the DLP2100 is on wheels so once the base of the box is removed the finisher can be put down and wheeled into place. It’s not exactly easy to push but on a flat smooth floor it can be done.

Once in place the DLP is levelled and we add the Afinia L901 Plus printer. This sits on the flat base to the left, above the material unwinder.

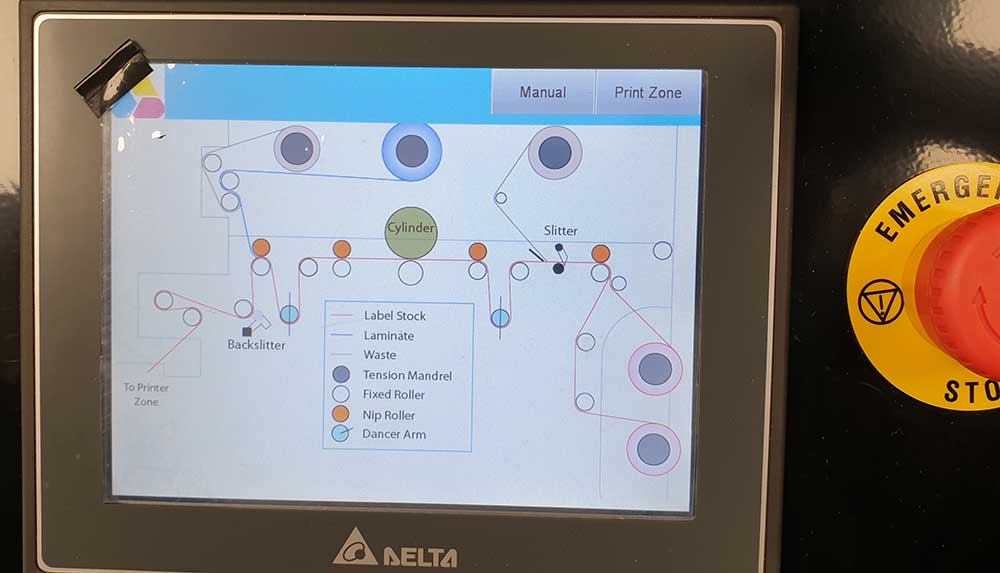

The next step is really getting the machine threaded up with material and laminate, adding the die and lining up all of the guides. At HD Labels we fully commission the machine and everything is lined up and tested before we start any training. Each of our Engineers are fully approved by Afinia and HD Labels have been one of the leading Afinia distributors globally for the past 8 years.

Once all is installed, tested and training complete we will continue to support this customer for years to come.

Here is the Afinia DLP2100 Digital Label Press in action. If you would like to find out more on the DLP2100 or would like samples & demonstrations please let us know. HD Labels are a full approved Afinia distributor with a fully trained sales and tech support team.

Talk to the TeamThe Afinia DLP2100 Digital Label Press is a total label solution. Powered by the Afinia L901 Plus using Memjet technology and Watershield inks. Print, Laminate, Cut, Strip, Slit & Rewind your labels in one pass at speeds of up to 18m per minute.